3.1.3 Batch preparation operation

Batching is considered to be one of the most critical and essential operations in feed manufacturing. Lack of proper batching can lead to reduced diet uniformity, affecting not only animal performance but regulatory compliance as well.

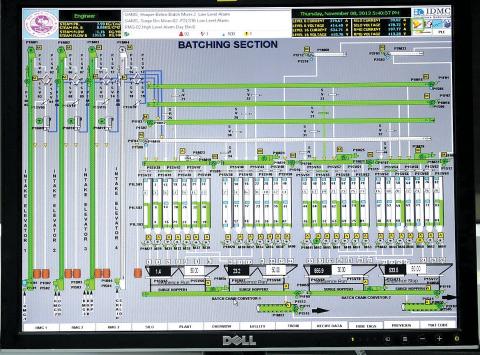

Fig. 3.3 Computerized batching

The batch section of the plant consists of mainly pre-weighing bins, bin dischargers, weigher, hopper below weigher, chain conveyor and elevator. Formulae containing various available ingredients stored in the RMG/ Silos based on least cost to produce a specific type balance concentrate feed are made available by the Nutrition Officer for production. All such ingredients are stored in various pre weighing bins. Plant is provided with automatic microprocessor controlled batching system for accurate batching (Fig. 3.3). As per feed formula, desired quantity of each ingredient is discharged from the pre- weighing bins (Fig. 3.4) into the batch weigher (through VFD operated bin discharger for more accurate batching) to make a complete batch of 1.0/ 1.5/ 2.0/ 2.5 MT (as per plant capacity) including molasses. Batching operation is done from the control room. Once the batch is ready, it is transferred from the batch weigher to the hopper below batch weigher through a pneumatic flap and the batch weigher starts getting the next batch. The complete batch is then mechanically conveyed to hopper above hammer mill in grinding section through batch chain conveyor and elevator. The quality control officer must periodically check the accuracy reports of the computerized batch preparation system to ensure that weighing of individual raw material is in accordance with the feed formula and that large deviation of set and achieved weights are not taking place. Periodically, he should also check the accuracy of the weigh scale and calibrate the same if necessary

Fig. 3.4 Pre-weighing bins